As the year ends and we reflect upon the challenges and triumphs experienced by our team at Amba Products during 2022 - there were many lessons learned. When global supply chain issues were made worse by a natural disaster in our area, our team quickly pivoted to continue business operations. Though this was a difficult time for Amba, our diligence in working through the issues caught the attention of our industry peers.

In October 2022, the Decorative Plumbing and Hardware Association (DPHA) recognized Amba with two awards. One that celebrated the Amba customer service department and the other for the product of the year. The DPHA acknowledging Amba while facing unprecedented logistics and operations challenges highlights our resilience and dedication to always putting customers first. For our team, receiving these honors is much more meaningful because they came at a time we were battling with an immense amount of adversity.

However, it’s been a challenging couple of years for businesses worldwide. As congested ports and disruptions in air and rail freight resulting from COVID-19 continued taking their toll on the global economy. Many companies struggled to stay afloat. Small businesses have experienced extraordinary challenges that require creative solutions. Our team worked tirelessly to adjust to rising operations costs and significant shipment delays. But in September 2021, business was halted at Amba Products when a storm hit the area, causing power and telephone outages and flash flooding that washed away the bridge used to access the headquarters.

In the aftermath of the storm, our team had to move business operations in less than 30 days while figuring out how to keep up with customer orders during such chaos. The absence of the bridge made it impossible for delivery drivers to access the building, further contributing to strained logistics issues. To make matters worse the municipality failed to address the problem promptly, leading to nearly a year of disruptions to operations. During this time, the building was only accessible via a makeshift bridge supplied by the DOT, and the damage caused by the storm affected our distribution, sales, and administration departments.

Operation Transition

In a month, our team transitioned from in-person to primarily working from home, with some employees traveling between the office, warehouses, and the post office when needed. The move came with no assistance or timeline for the newly constructed bridge from the city government. As uncertainty hung in the air, Amba General Manager Harris Wattles focused on the staff.

“I needed to ensure that my team had the means to work from home but also not feel like they were isolated or left by the wayside," said Wattles. “We had to purchase some new equipment like laptops, printers, and supplies to make the transition to working remotely smoother,” he continued.

Then, our team focused on fixing technical issues brought about by the phone system that crashed during the storm and the unforeseen shift to working from home. Due to the unusual circumstances, we needed to get creative with the solutions.

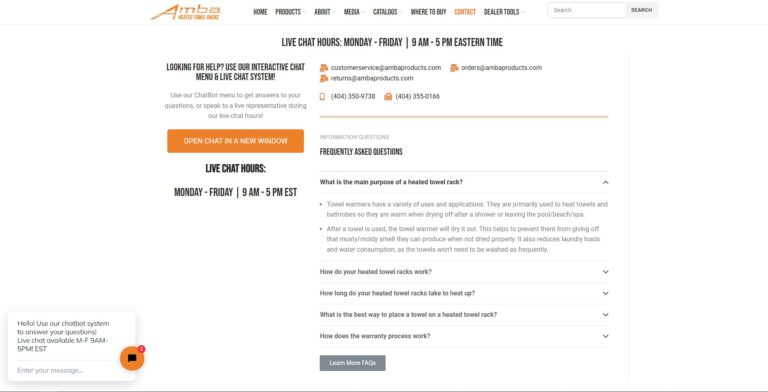

“We built out more robust tools for our website to give greater access to information on stock and POs for sales associates; chat system on the website and new VoIP phone system for more and improved communication channels to connect with Amba," Wattles added. “Many of the solutions will continue to be utilized well beyond completing the bridge project," concluded Wattles.

Distribution Difficulties

With a literal absence of a road to receive and ship products, the immediate challenge was figuring out how to continue distribution to customers. Together, our team processed orders manually, taking turns loading personal vehicles with boxes, driving to the post office, and shipping each transaction. It wasn’t long before we realized that the everyday operations at Amba needed to be reworked to keep the business running. We eventually settled on two separate storage facilities, one that was a third-party logistics company that assisted with storage, picking, and packing half of the orders. And the other warehouse, located about forty minutes from the headquarters, stored another portion of the inventory. But it did not help with shipping products, so an Amba employee made special trips to the facility to process orders and prepare shipments. The process added a lot of complexity to shipping and was very time consuming.

Even with two additional warehouses, some orders required processing at the Amba facility. These items called for employees to scale the makeshift bridge while carrying boxes and paperwork one by one. Additionally, distribution employees worked 12-to-14-hour days to ship orders out on time. Some even stored, received, picked, and packed accessory orders at their homes to help keep up with sales volume.

Sales Setbacks

With logistical gridlock happening across the globe, our sales team had grown accustomed to extended lead times on orders. Still, uprooting operations at the Amba headquarters further exacerbated the problem. Moreover, the storm affected the phone system, causing it to malfunction and delaying responses and feedback to territorial managers and sales associates. When employees began working from home, they no longer had access to paperwork, marketing materials, and the mail they needed to effectively do their jobs.

As our team became accustomed to the new working process, we were able to get the lead times back to normal despite the major logistic issues that occurred. We then eliminated our traditional phone system and upgraded to a VoIP system that allowed calls to be routed and responded to by the sales department. We added a new inventory check link on the website that helps salespeople to keep up to date with our inventory. The new communications tools helped our team to be more productive at a critical time. Finally, we acquired a portable storage unit to house sales materials so that personnel could access samples and product literature for the sales team.

Customer Service Challenges

The phone system outage was particularly difficult for our customer service team. It left them incapacitated and unable to make or receive calls. When calls did come through, they were often routed to the incorrect department making the situation more challenging. Because of the outage, the team was inundated with emails, making the process feel overwhelming. In the weeks leading up to the shift to working from home, customer service employees played an integral role by pitching in manually processing orders with the distribution team. They worked long hours helping to load, unload, and ship items to their destinations.

After implementing the new phone system, the department could better assist customers with their needs and calls transferred to the correct lines. The management team also decided to add a chatbot on the website to help handle customer issues online, which helped reduce the volume of cases managed over the phone. Once the company switched to working remotely, the departmental duties mostly returned to normal but included a few tasks to help other departments.

Lessons Learned

At a time when many businesses were addressing the supply chain difficulties presented by a worldwide pandemic, Amba Products was also dealing with the certainty that our business operations would need to shift. The experience helped us recognize the shortcomings in our organization and forced us to face them head-on. Our team was nimble and worked together towards a common goal, keeping the company on track - ultimately allowing it to thrive.

“All of our team members stepped up to the call of duty, and I am beyond thankful and proud to have them on our team. It took the efforts of each one of them to keep things going as they did," added Wattles.